Features

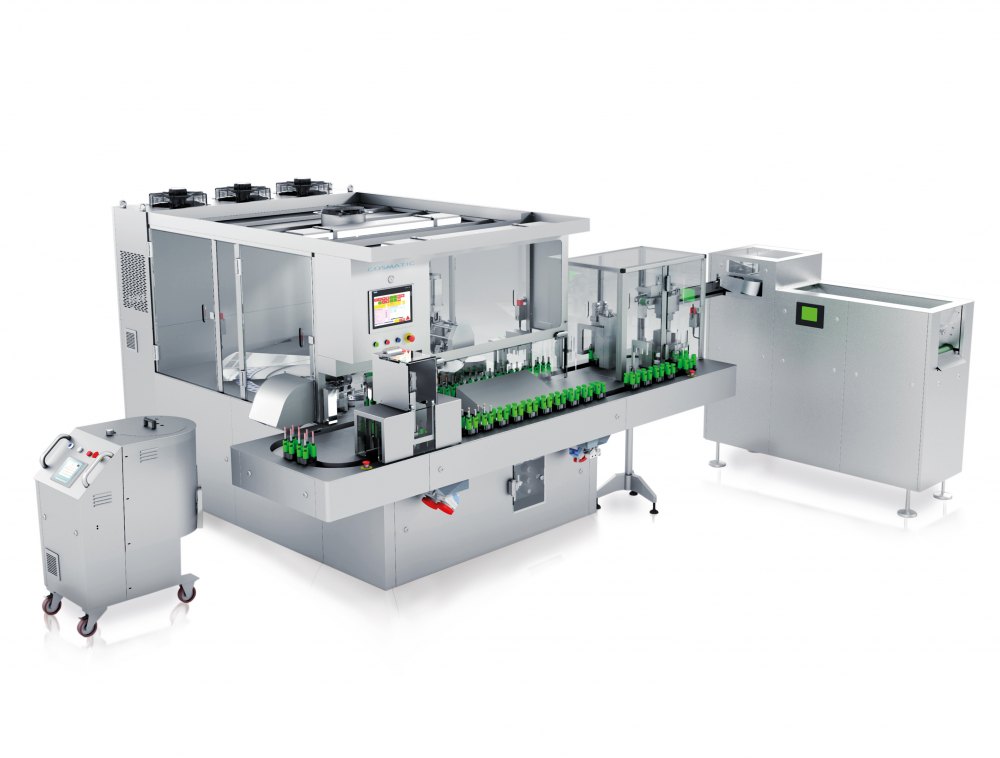

Lipstick moulding machine S 2000 N based on the silicone mould technology with belt conveyor and auto-loader for empty bases.

- Complete with 1 or 2 melting tanks 35 liter, stand alone

- Silicone moulds heating by infrared radiation, short wave (patented)

- Dosing by means of doser with 2 gearing nozzles or volumetric doser

- Cooling by forced air circulation, double refrigerator inside the machine, temperature -20°C, automatic defrosting

- Pick and place for the pick and place operation of 4 cases by means of grippers to the demoulding group

- Demoulding by means of mechanical system without membranes (patented)

- Cases store by means of belt conveyor with pallet for cases

- Controls of the machine by means of colour touch screen with software with manual and automatic menu

- Easy and quick mould change

- Fast colour change, moulds cleaning at colour change is not needed

- Stick perfection, stick shapes and logo according to the customer’s requirements

Technical data

| Output: | up to 2400 pz/h |

| Operator: | 1 |

| Silicone Moulds: | 160 |

| Cooling System: | -20° C |